Ice Bank Tank Working

- Home

- Ice Bank Tank Working

Ice Bank Tank is a small refrigeration system that cools down the unit for several hours until the energy in the form of ice is made to be used later on. The stored ice later used to cool the water or milk and used in the process the next day. Process Engineers And Associates is one of the leading Ice Bank Tank Manufacturers. To know the Dairy Ice Bank Tank Working Principle, check the steps mentioned below.

Step By Step Ice Bank Tank System Working:

- Step 1: During night time, water that contains 25% ethylene or propylene glycol is cooled by a chiller built within it. That solution circles inside the heat exchanger within the Ice Bank tank, freezing 95% of the water that encompasses the heat exchanger inside the tank. The water encompassing the heat exchanger stays inside the tank even after the process, which keep it protected against any damage.

- Step 2: Ice gets formed uniformly via counter-flow-heat exchanger tubes, which can be used later in the process when there is low power or no power.

- Step 3: During peak hours, the glycol solution circulates through the storage tank and deliver the stored energy to offset electric chiller cooling. Due to this, work never gets hampered and boosts productivity as well.

- Step 4: Lastly, a fan within Ice Bank Tank blows the air over the coils to deliver cooling to obtain chilled milk or water, without breaking the banks.

From the above, Working Of Ice Bank Tank is clear and if you are interested, place your order for the Ice Bank Tank System now.

Related Products

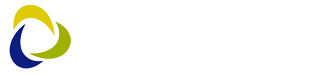

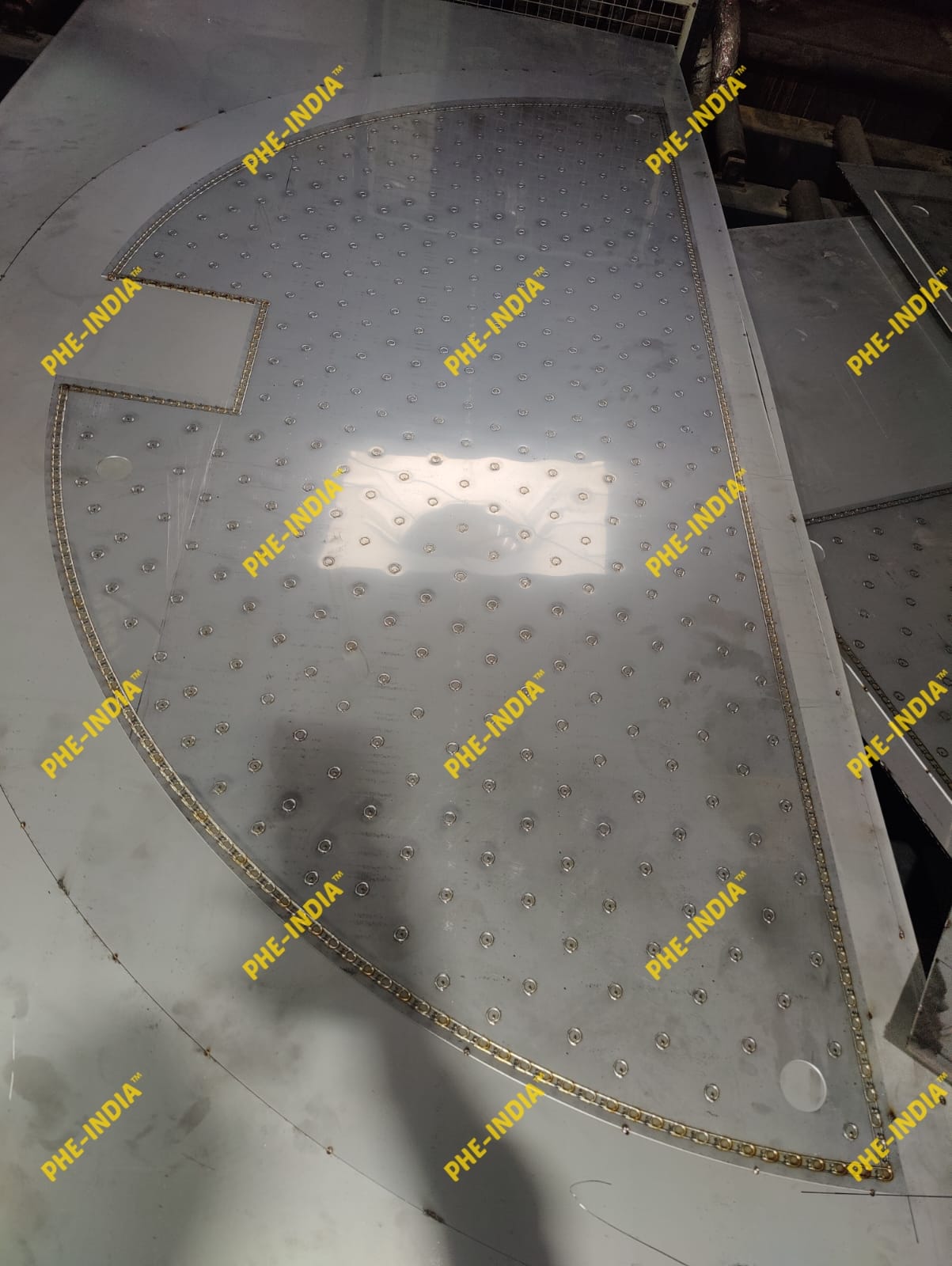

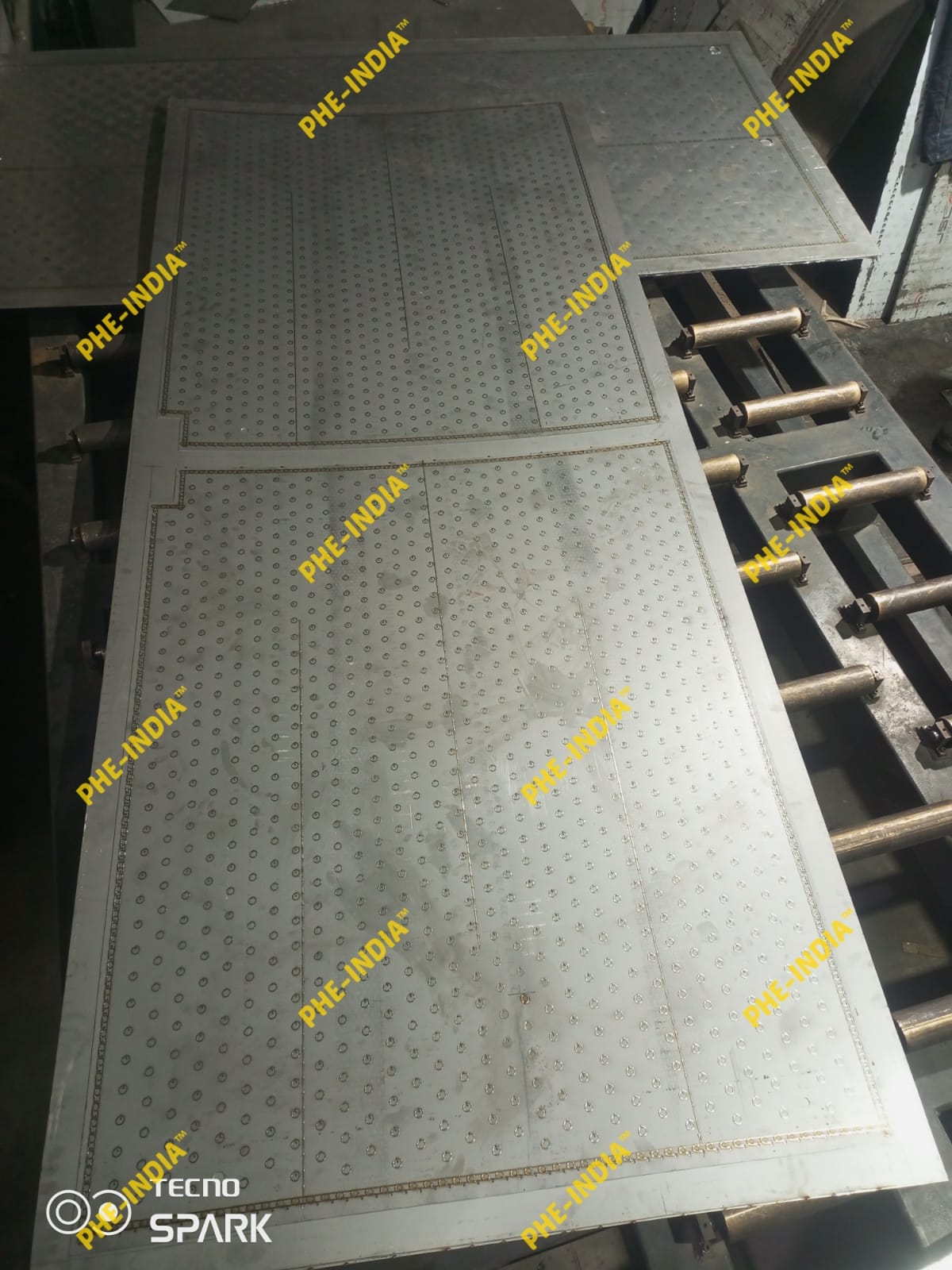

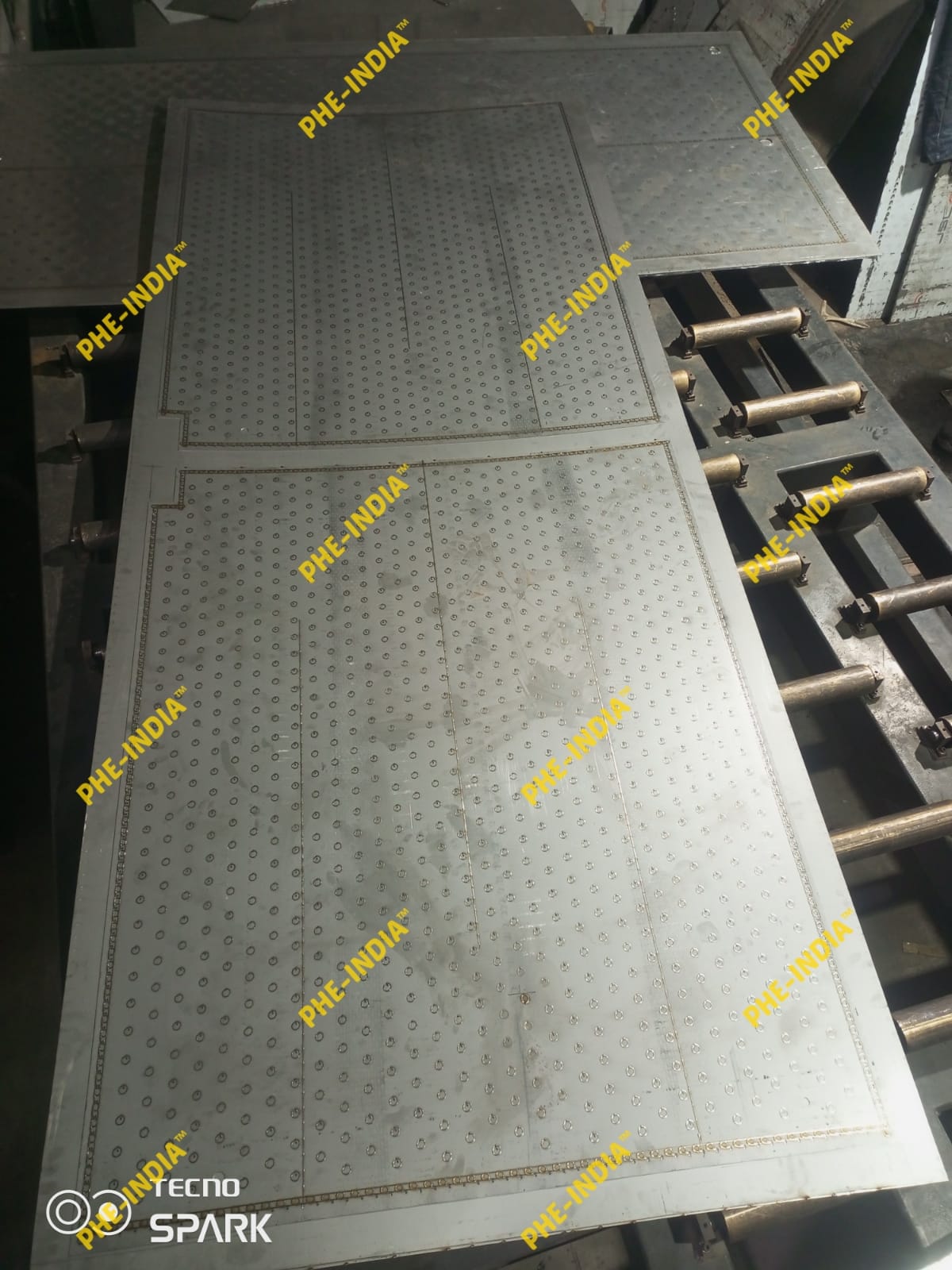

Pillow Plates

Pillow Plate is a heat exchanger designed for industrial heating or cooling of products. Available in single and double embossing, this Pillow Plate is accurate and used as a manufacturing component for tanks for Milk Refrigerators, Ice Cream Tanks

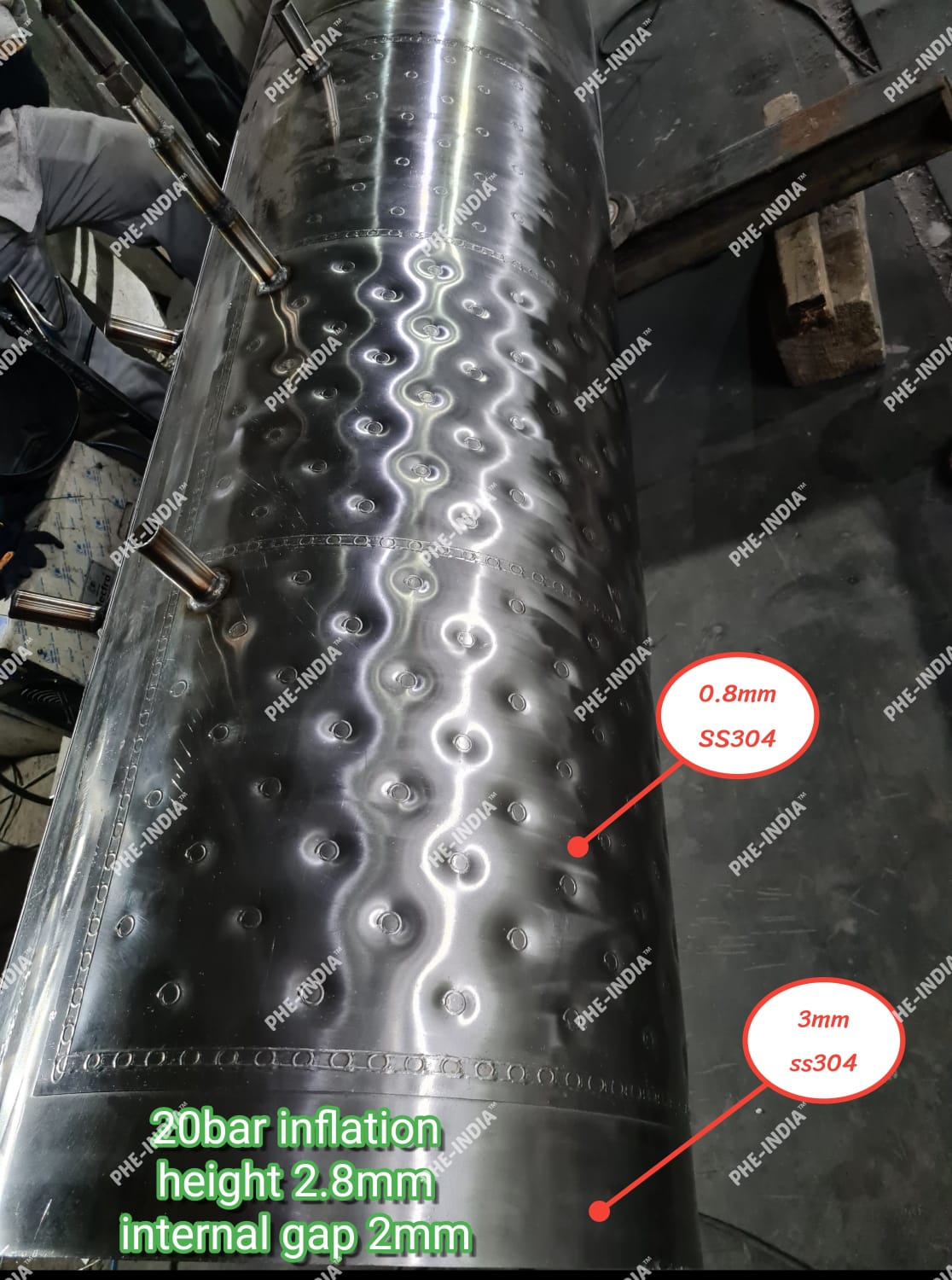

Industrial Pillow Plate

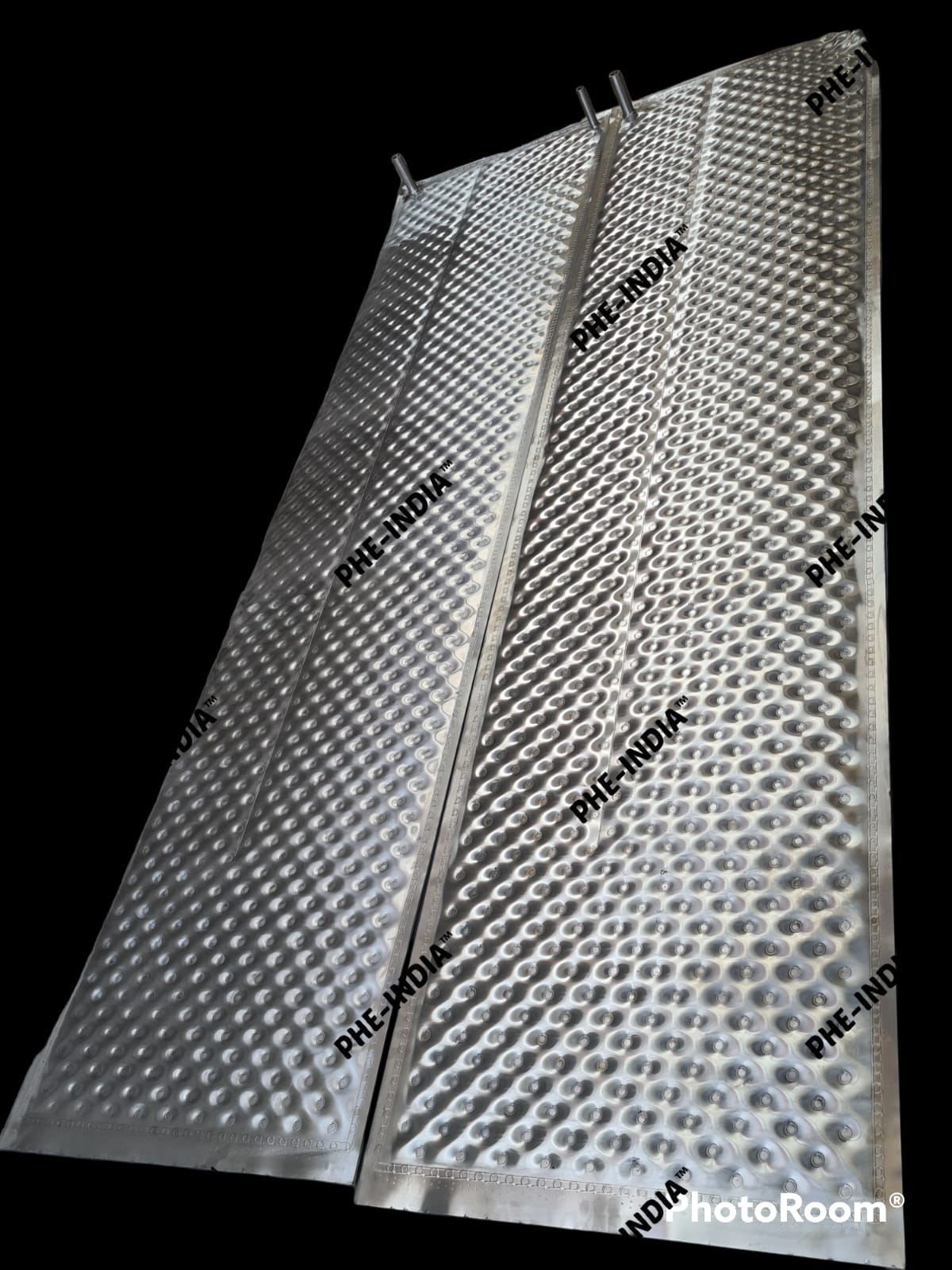

Industrial pillow plates are used widely in dairy, beverage and other industries. Process Engineers And Associates uses the latest technology to inflate these plates and the weld is strong enough to withstand several years of usage.

Pillow Plate Heat Exchanger

Comprising of thin stainless steel plates along with internally fitted gaskets, our heat exchangers are utilized in several industries. Two channels, through which hot and cold liquids flow, maximize the heat transfer surface and do the job quite efficiently.

Stainless Steel Pillow Plate

Our pillow plates are known for providing high thermal performance in a wide variety of applications. Driven by the idea of delivering world-class products to our clients, we are never satisfied with substandard products.

Immersion Pillow Plate

Process Engineers And Associates manufactures these immersion pillow plates as per the set standards of the industry.

Vertical Pillow Plate

Pillow plates are heat exchanger plates which are available in vertical as well as horizontal designs and in different other configurations to suit the different industry needs.

Single Embossed Pillow Plate

Single Embossed Pillow Plate is designed to be used in specific applications that require cooling or heating and thus, available in different standards, materials and thicknesses.

Double Embossed Pillow Plate

Double Embossed Pillow Plate is used as a heat exchanger for liquids, granules and even powders.

High Efficiency Pillow Plate

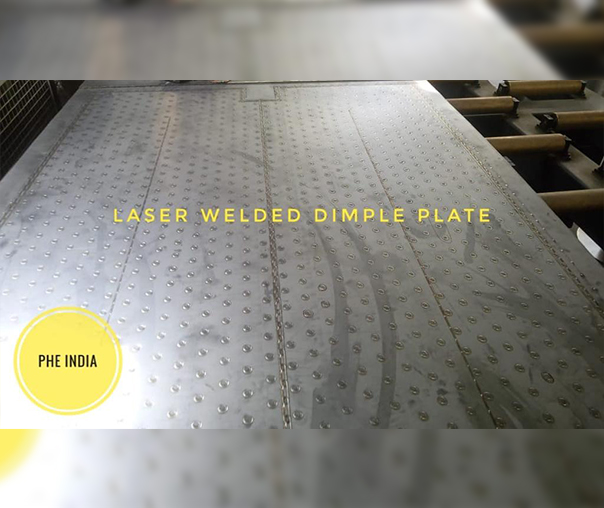

Pillow plates are also called as dimple or thermo plates. These consist of stainless steel sheets, which are laser welded together by welding a custom circle weld pattern.

Laser Welded Pillow Plate

Pillow Plates have a huge industry and thus, these are available in a versatile panel-type heat exchanger that can be welded, formed or fitted.

Laser Welded Thermo Pillow Plate

Process Engineers And Associates bring to you an advanced range of Pillow Plates, customized as per the need of your industry.

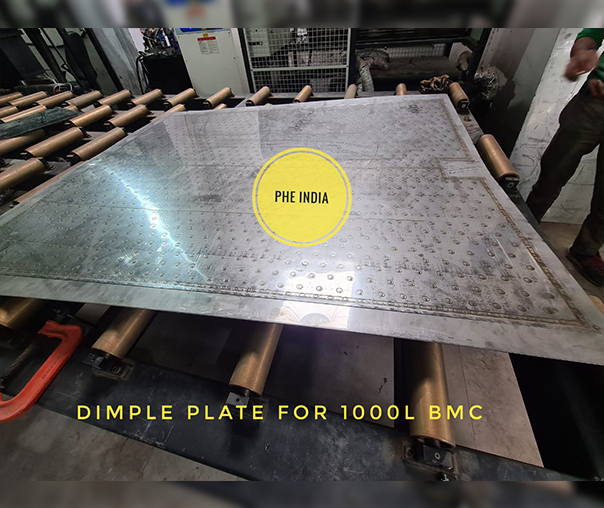

Pillow Plate For Bulk Milk Cooler

Pillow plates are used widely in the dairy industry and we offer a complete range of these plates to meet the diverse requirements of the country.

Pillow Plate For Cooling And Heating

Process Engineers And Associates is one of the highly appreciated Manufacturers of Pillow Plate for Cooling and Heating based in Delhi.

Pillow Plate For Dairy Industry

As a dynamic organization, we always look for more ways to improve our products so that we can serve our clients better.

Pillow Plate For Energy Saving Heat Exchanger

Heat exchangers can be found in almost every process plant. The dependency of these plants on these heat exchangers is crucial and much of the energy is spent on their performance.

Pillow Plate For Evaporator Plates

Process Engineers And Associates handles everything from the design, manufacturing to the delivery of these pillow plates.

Pillow Plate For Falling Film Water Chiller

A falling film water chiller, as the name suggests, is used for cooling water to the desired temperature.

Pillow Plate For Heat Recovery From Water

Our designed pillow plates for heat recovery from water are highly efficient and effective in their operations.

Pillow Plate For Immersion Chillers

A key benefit of using these pillow plates for immersion chillers is that you can cool liquids that are heavily contaminated without the heat exchanger becoming dirty.

Pillow Plate For Milk Cooling

Dairy industries always require high-quality pillow plates for cooling the milk being processed in the facility.

Pillow Plate For Milk Tanks

Process Engineers And Associates is a name that has become synonymous with premium quality pillow plates in the industry.

Pillow Plate Jacket Tank

Pillow Plates can be explained as a product that serves the application of a heat exchanger.

Pillow Plate Laser Welding Machine

The Pillow Plates Laser Welding Machines are also known as dimple plates and consist of two stainless steel sheets that are laser welded together.

Pillow Plate Reactor

Made with high-quality stainless steel, the Pillow Plate Reactors are used in multiple applications, and have a myriad of advantages to offer in the beverage making industries

Pillow Plate Plating

A metal heat exchanger that is formed by inflating is called as pillow plates or dimple plates.

Pillow Plate Design

Pillow plates are made up of stainless steel sheets and used in multiple industrial cooling and heating activities.

Pillow Plate Pattern

The manufacturing of thermo plates/ pillow plates is done to facilitate the work of different food and beverage industries.

Beer Tank

Are you dealing in the brewery industry? If yes, you shall seek the support of one of the preeminent Beer Tank Manufacturers In Delhi – Process Engineers And Associates.

Beer Tank Plate

The process of making beer includes include malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering, and packaging.

Beer Fermentation Tank

Beer gets its alcohol content and carbonation through the process of fermentation.

Stainless Steel Beer Tank

Stainless steel is an eminent alloy of the steel and it is prudent to use it for the formation of Beer Tank.

Beer Brewing Tank

The beer industry makes the use of big tanks for the purpose of brewing.

Beer Storage Tank

Beer storage tank is not just useful for storing the beer, but also for initiating fermentation process.

Brewery Tank

The brewery tanks serve the purpose of storage, brewing and fermentation of the beer.

Brewery Fermentation Tank

Brewery Fermentation Tank has a major role in the success of fermentation and procuring the wines for ages.

Brewing Tank

Are you looking for Brewing Tanks? Process Engineers And Associates – one of the most zealous Brewing Tank Manufacturers in Delhi builds the equipment used in beer and wine industries.

Brewing Fermentation Tank

The choice of Brewing Fermentation Tank is always a major concern and one needs to be very precise while doing the same, as it can otherwise affect the quality and taste of their wine and the process.

Wine Tank

Wine Tank made of stainless steel are best and ensure better fermentation, transportation and storage, and this has given the boost to their demand in wine making industries.

Wine Tank Plate

Are you in search of pillow plates for you wine tanks? If yes, it’s the right time to put an end to your quest. Process Engineers And Associates has its position marked among the market-leading Wine Tank Plate Manufacturers In Delhi.

Wine Fermentation Tank

If you are going to step in the business of winemaking, you shall purchase wine fermentation tank from one of the formidable Wine Fermentation Tank Manufacturers In Delhi.

Stainless Steel Wine Tank

There is a high demand for tanks made with stainless steel in the winemaking industries as they are highly pivotal to increase productivity and assure the quality of the wine.

Stainless Steel Wine Fermentation Tank

Fermentation is a crucial process used while making wine and it cannot be ignored.

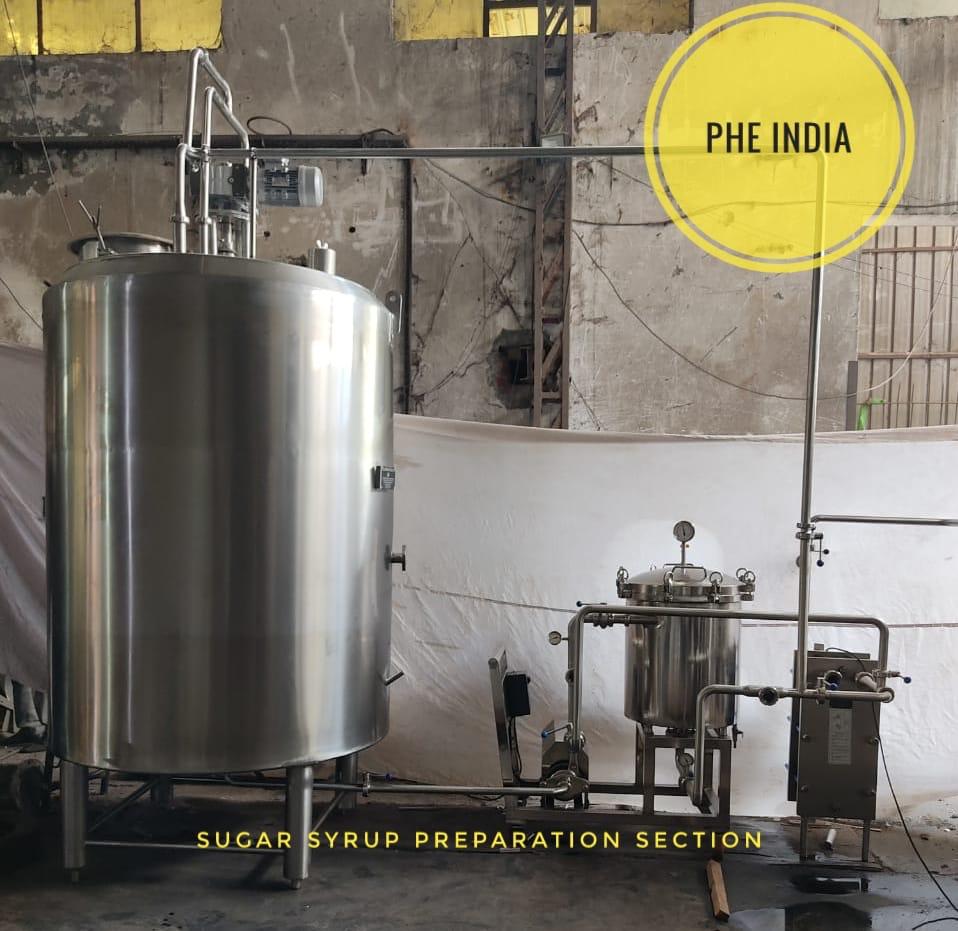

Wine Making Tank

The process of making wine can be simplified with the use of winemaking tank offered by one of the zealous Wine Making Tank Manufacturers In Delhi – Process Engineers And Associates.

Wine Processing Equipment

Wine fermentation tank and pillow plates are some of the essential types of equipment used in a winemaking industry.

Dairy Tank

Dairy industries must need a Dairy Tank for the process of fermentation and storing such a huge quantity.

Bulk Dairy Tank

If you are planning to buy Bulk Dairy Tank, Process Engineers And Associates is the name that has to be on your contact list.

Dairy Tank Plate

To buy a fleet of Dairy Tank Plates in standard or customized options for your dairy industry, Process Engineers And Associates is the one you can contact.

Stainless Steel Milk Tank

Are you planning to buy Stainless Steel Milk Tanks? Looking for the right platform to purchase only the best? Process Engineers And Associates – one of the top-notch Stainless Steel Milk Tank Manufacturers in Delhi have manufactured customized range for you.

Tank Plate

The tank plates are useful for heating or cooling the tanks in multiple industries.

Process Tank Plate

In multiple industries, the need for process tank plate has raised beyond measure.

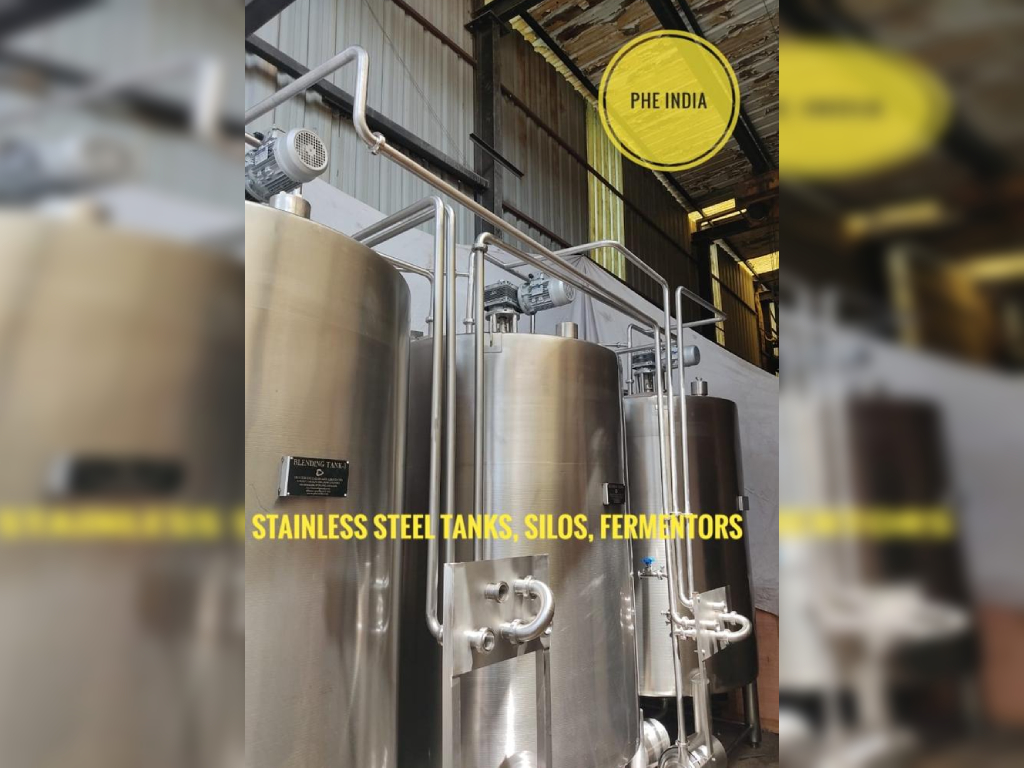

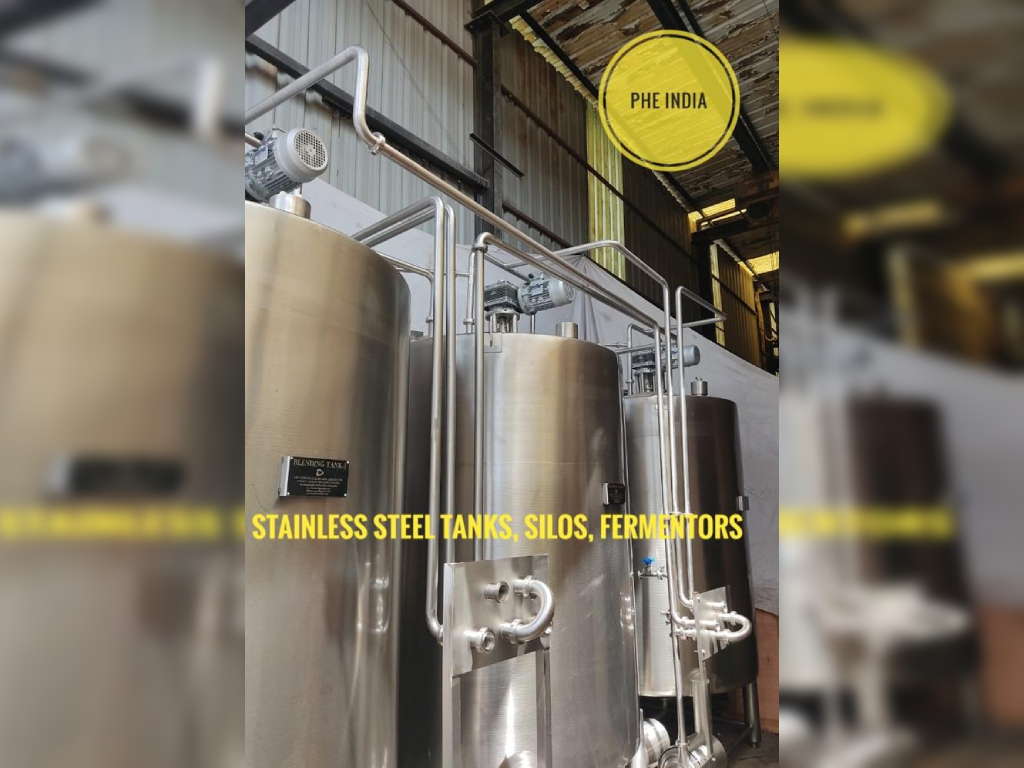

Fermenter

The dairy industries have a diverse need of fermenter to process the milk in different forms.

Stainless Steel Fermenter

If you are looking for a fermenter that could ease your industrial loads and go on for a long period of time, you shall consider visiting Process Engineers And Associates – one of the leading Stainless Steel Fermenter Manufacturers In Delhi.

Fermentation Tank

Multiple industries consider Process Engineers And Associates as one of the most distinguished Fermentation Tank Manufacturers In Delhi because we stand tall on our commitment to deliver quality products.

Conical Fermenter

The cone shape of the fermenter gives it a distinguished look and also helps in its proper functioning.

Industrial Fermentation Tank

The process of industrial fermentation is the one in which the microorganisms or eukaryotic cells purposely used to fermentate the products into something else, such as yeast, beer and wine.

Conical Fermentation Tank

The fermentation tanks see diverse use in distinct industries. Process Engineers And Associates has gained immense reputation and recognition among the top-notch Conical Fermentation Tank Manufacturers In Delhi.

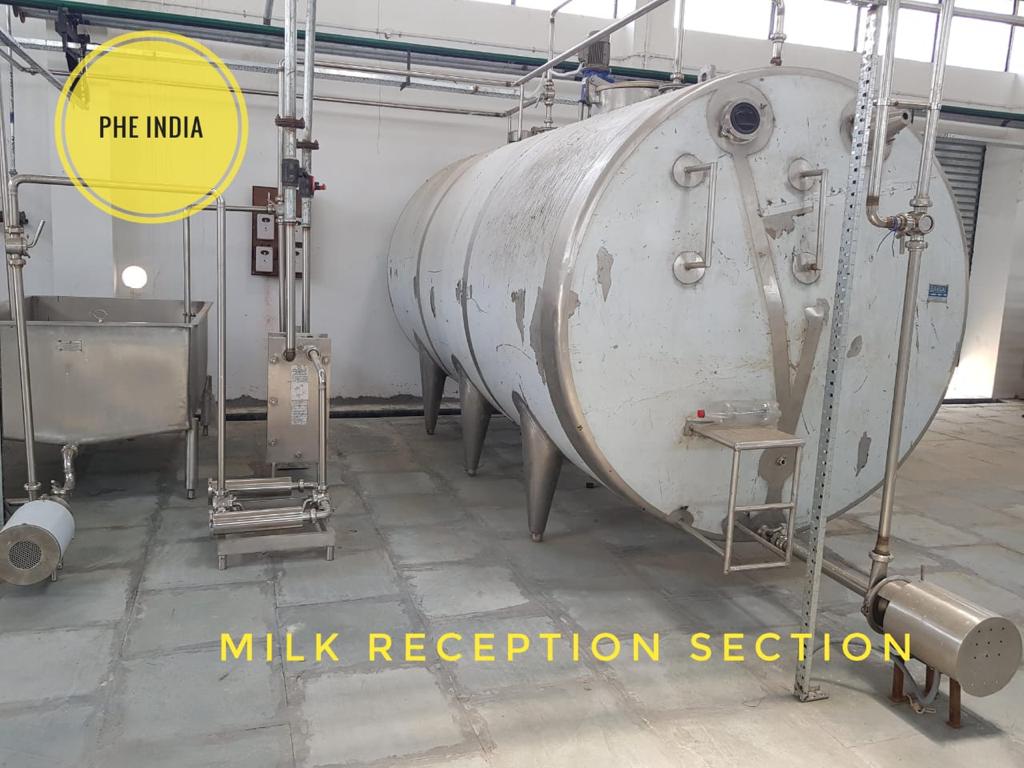

Bulk Milk Cooler

Our bulk milk coolers are made from food grade material to ensure there is no contamination during the processing.

Bulk Milk Chiller

Our milk chillers are ideal for preserving or even improving the milk quality by preventing the development of bacteria in the stored milk.

Single Embossed Dimple Plate

Process Engineers And Associates is one of the most dependable Single Embossed Dimple Plate Manufacturers In Delhi.

Thermal Dimple Plate

Process Engineers And Associates has its principal core competence in manufacturing world-class thermal dimple plates.

Ice Storage System

Ice Storage System is used for building ice or thermal energy for using further. Process Engineers And Associates is one of the most determined Ice Storage System Manufacturers in Delhi.

Ice Bank Tank

Ice Bank Tank is a new technology used for storing thermal energy. They have a wide application area indeed and is mainly used for chilling water to 1°, which is further used for cooling milk or during the pasteurization process in dairy milk industries.

Ice Bank Silo

Ice Bank Silo is a large ice surface which eases the process of cooling products more efficiently irrespective of extreme load peaks.

Immersion Chiller

Immersion Chiller is designed to circulate cooling fluid through its copper/stainless steel coil, which is placed in the hot wort to drop down the temperature quickly for fermentation.

Falling Film Chiller

A Falling Film Chiller is a kind of water cooler whose application depends on pillow plate technology and is suitable for cooling your products.

Dimple Jacket Laser Welded Tank

Process Engineers And Associates is one of the most reputed Dimple Jacket Laser Welded Tank Manufacturers In Delhi.

Laser Welded Tank Components

Process Engineers And Associates, being the most preferred platform to avail laser welded tanks, is also one of the highly appreciated Laser Welded Tank Components Manufacturers In Delhi.

Laser Welded Tank Shell

These laser welded tank shells are used to heat or cool the components stored in the tanks. The higher heat transfer speed and elimination of the need for post-processing make them highly preferable in several food processing industries.

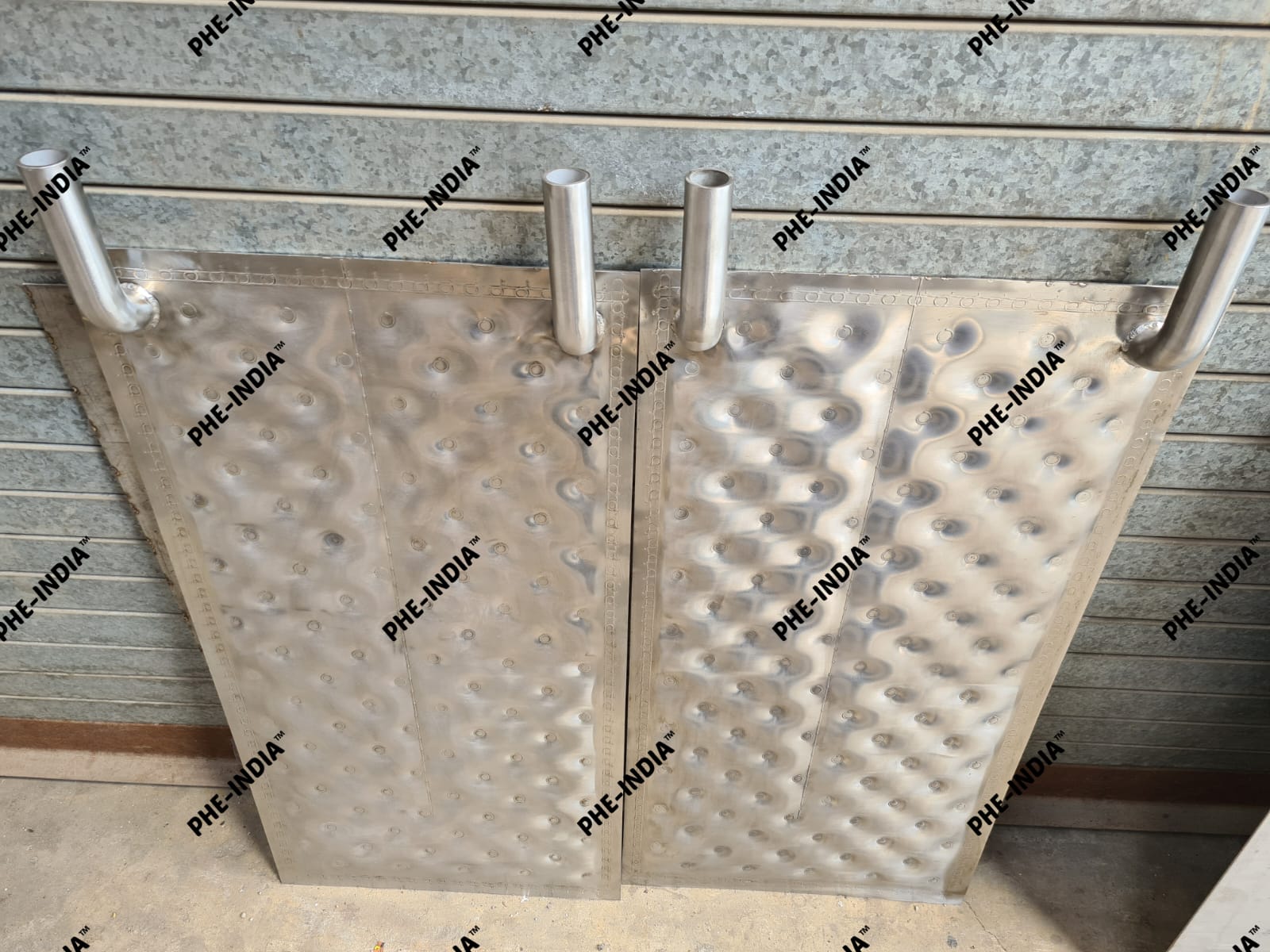

Flanged And Dished Tank Head

Process Engineers And Associates fabricates a wide range of flanged and dished tank heads. Utilized in a broad variety of processing industries, these components ensure quality standards and safety in these facilities.

Immersion Heat Exchanger

Immersion heat exchangers can be either a single plate or multiple pillow plates assembled together. They are immersed in a fluid to achieve the desired heating operation.

Clamp On Heat Exchanger

Clamp-on heat exchangers is a versatile way to heat or cool the exterior of a tank or vessel.

Laser Welded Plate

Laser Welded Plate is a custom-made plate consists of two stainless steel sheets welded together by welding a circle pattern with laser technology.

Process Engineers And Associates was established in the year 2013, under the efficient headship of Mr. Mahesh Chand Chawla. His deep and in-depth knowledge in the domain of pillow plates have made us stand amidst the leading manufacturers, suppliers and exporters in India. The Ice Bank Tank Working is available in various sizes and specifications to meet the requirements of the buyers and application areas. The array includes Pillow Plates, Industrial Pillow Plate, Pillow Plate Heat Exchanger, Immersion Pillow Plate, Embossed Pillow Plate, Brewing Tank, Brewing Fermentation Tank, Wine Tank, Wine Making Tank, Wine Processing Equipment, and more.

The Ice Bank Tank Working is a type of industrial cooling or heating products, which are used for various applications. Thus, this has become an inevitable part of Cooling Milk, Soft Drink, Wine/Beer, Pharmaceutical, Chemical, and Meat Processing industries. The use of premium quality raw materials also makes the Ice Bank Tank Working unique in its efficiency and performance.

The attributes of the Ice Bank Tank Working, offered by us, are as listed below:

- Quality - Committed to deliver excellent products, various measures taken to meet the world-class quality standards.

- Advance working - a team of professionals work on the R&D to ensure Ice Bank Tank Working is completely as per the requirements of the buyers and application areas.

- Wide Range - the array is huge and diverse to meet the requirements of the application areas. There is no alternate available.

- Wide network - strong business network have made the Ice Bank Tank Working available in every corner of the word.

Yes, customer support is available. All you need to do is fill in the ‘Enquire Now’ form available on the website. You can call on +91-8527455996 or drop an email on info@phe-india.com to place order for Ice Bank Tank Working. You can also visit us at our location E-78, Sector 63, Noida – 201307, Uttar Pradesh, India.

As there is no alternate available to our Ice Bank Tank Working, when it comes to quality and efficiency, we have become the foremost choice of the buyers. In addition to this, some other reasons that make us stand among the trusted Ice Bank Tank Working Manufacturers in India are:

- Excellent quality & extensive range

- Team of highly experienced professionals

- Advance manufacturing facility

- Huge list of prestigious clients

- Industry leading prices.

Copyright © 2021 Process Engineers And Associates | All Rights Reserved . Website Designed & SEO By Webclick® Digital Pvt. Ltd. Website Designing Company India